Potassium formate didn’t just pop up in a modern lab overnight. Rooted in classic organic chemistry, chemists first made formic acid in the 17th century using ant bodies, as wild as that sounds. Over time, industrial minds saw the need for better, safer de-icing agents and drilling fluids, pushing manufacturers to synthesize potassium formate by neutralizing formic acid with potassium carbonate or hydroxide. Fast-forward past a few decades of tweaks and patents, and the compound has become a mainstay in fields where high performance under low temperatures means the difference between success and shutdown. Its growth reflects a larger trend: society keeps searching for safer, more efficient chemicals without the hazards old-school options brought along.

Mention potassium formate today and you’re likely pointing at a white, odorless powder or a clear liquid solution. Factories favor this salt because it dissolves easily in water and does not attack metal equipment with the same zeal as options like calcium chloride. It thrives in industries that demand fast-acting de-icers, heavy-duty heat transfer fluids, and drilling fluids for oil and gas projects. When it comes in solution, concentrations often hover between 50% and 75% by weight, tailored to meet the job’s challenge.

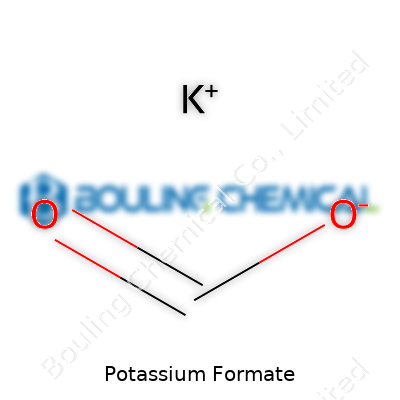

Potassium formate boasts a chemical formula of HCOOK and a molar mass of 84.12 grams per mole. It holds a melting point of about 167°C, which means it stands up to some real heat. The salt carries high solubility in water, forming solutions that resist freezing well below the comfort zone of most inorganic alternatives. One thing I always found interesting: its pH leans toward alkaline, which gives added protection to metals in industrial environments. Unlike some salts that leave a gritty mess, it dries down clean, which has built its reputation among those working in airport ground crews and oilfield teams.

Regulatory agencies and buyers expect manufacturers to meet strict technical benchmarks. Purity usually exceeds 98%, with low traces of metals and chlorides. Users often check specs such as solution concentration, pH in 20% solution, density, and heavy metal content. Packaging ought to carry hazard statements in line with GHS, clear batch numbers, and emergency contact details. Manufacturers stamp their barrels and bags with not just compliance labels, but clear handling instructions recognizing the real risks beyond the paperwork.

Most often, potassium formate gets produced in a reaction between potassium hydroxide or potassium carbonate and formic acid. The process runs exothermic, meaning it kicks out heat and calls for careful engineering controls. Plants use stainless steel reactors to prevent side reactions or corrosion. Once the reaction finishes, the resulting mixture goes through filtration to pull out any leftover impurities. Final steps include concentration by evaporation, especially for solution sales, followed by quality checks designed to catch anything off-standard before shipping. Automation has tightened the procedure, but any plant manager will tell you: making a pure, consistent product takes more than just a good process flow diagram.

Chemically, potassium formate reacts with strong acids, trading out its potassium for a more attractive ion in the exchange. It serves as a mild reducing agent and finds occasional use in lab syntheses where a gentle touch is needed. It also acts as a ligand source in metal-catalyzed reactions. In water, it readily dissociates to release the formate ion, which brings unique freezing-point depression qualities and makes it practical in brine formulations. If you introduce oxidizers, decomposition can yield carbon dioxide and water, releasing energy, which presses the point: always handle with respect around incompatible chemicals.

Walk through a technical manual, and you might see potassium formate under several aliases: Potassium methanoate, Formic acid potassium salt, HCOOK. On global markets, companies might push the same salt under brand names that promise “safe melt” or “eco-friendly de-icer,” but chemistry never changes. It’s worth knowing your synonyms and names in procurement and research to avoid mix-ups that can lead to costly delays.

Working with potassium formate doesn’t spark the same anxiety as handling stronger bases or acids. Still, it's not something you should treat like common table salt. Safety data sheets spell out the basics: guard your eyes and skin, watch for splashes, and use gloves. Breathing in the dust won’t do anyone favors, so dust control becomes key in powder operations. Spills call for quick, damp cleanup to prevent both slippage and environmental discharge. Storage asks for sealed containers in dry spaces – potassium salts readily suck moisture from air – and waste streams require care, since concentrated brines can disrupt water treatment processes.

Every winter, city crews and highway authorities reach for potassium formate to keep runways and roads ice-free without corroding their concrete and costly lighting systems. It's also the preferred choice in airport de-icing, where accidental spills into sensitive waterways force other salts off the runways. The drilling industry values potassium formate’s high density and low toxicity, letting it make drilling fluids that keep wells stable and fight freezing far underground. Cooling systems in food processing and refrigerant loops in ice rinks also favor its thermal stability and gentle impact on equipment, showing that this salt is just as comfortable in a stadium as it is in an oil field.

Academic and industrial labs continue to explore fresh angles for potassium formate. Teams look for novel ways to blend it with other salts to push the freezing point even lower, stretching its effectiveness against the meanest winter storms. Researchers check environmental impacts of its use at scale, monitoring how quickly microbes break it down in soil and water. Energy engineers probe its use as a hydrogen source or in fuel cells, while chemists craft new catalysts using its unique ionic properties. R&D doesn't just chase new applications; it looks for greener production methods and more efficient recycling strategies to keep the cycle sustainable.

Compared to plenty of legacy salts, potassium formate earns a reputation as relatively safe. Toxicological tests show it causes only mild irritation to skin and eyes if splashed – far less harmful than ammonia-based options. It breaks down quickly in the environment, with minimal risks for bioaccumulation. Studies in aquatic toxicity show the ion dilutes and degrades fast, which reassures water treatment operators. At high doses, potassium can stress sensitive organisms or people with kidney issues, but environmental monitors keep close tabs to prevent local overloading. Industry standards and ongoing research keep the spotlight on safe limits and long-term ecosystem impacts.

Potassium formate stands on a promising path. As pressure grows to replace old chloride salts blamed for infrastructure damage and aquatic stress, this salt offers a combination of safety and performance that’s hard to ignore. New transport and construction projects in colder climates demand solutions that won’t eat away at rebar or poison runoff. As more cities, energy companies, and manufacturers study their own carbon footprints, potassium formate’s ease of degradation and lower toxicity place it high on green procurement databases. Expect continued innovation in its production, more circular strategies for reuse, and stricter environmental benchmarks shaping how it’s made and applied. Labs keep probing for even safer and more powerful formulations, making this old stalwart a constant in the toolkit for industries chasing efficiency with a conscience.

Potassium formate looks like just another chemical on a long list of industrial ingredients, but this simple salt packs a surprising punch in the real world. My first brush with it came during a winter internship at an airport, when workers buzzed about a brine called “formate” that helped keep runways clear. At the time, I figured it was just another ice-melter. Turns out, there is a lot more going on.

Potassium formate makes a big difference on icy runways and highways. Traditional rock salt leaves metal corroded, plants struggling, and plenty of grit to sweep up. In contrast, potassium formate cuts through ice quickly and doesn’t leave that dirty residue behind. It breaks down less harmfully in water, sparing grass and streams in the area. In Norway and Sweden, airport authorities switched to it after environmental studies flagged traditional deicers for river pollution. The science is straightforward: less chloride means less stress on plants, aquatic life, and infrastructure. Planes and runways stay safer, and there’s less repair work in the spring.

Companies drilling for oil and gas lean on potassium formate for its ability to help keep drilling fluids efficient. In tough underground conditions, drillers don’t want their fluids freezing, foaming, or reacting negatively with rocks. Potassium formate helps tackle all three issues. Engineers like it because it boosts fluid density without making the mixture poisonous or corrosive, so equipment lasts longer. I worked with an engineer who swore by formate’s ability to protect sensitive electronics and seals during some pretty challenging drilling jobs in the North Sea. That advantage means fewer breakdowns, less downtime, and safer operations overall.

Large warehouses sometimes use potassium formate as a heat transfer fluid inside cooling systems. It doesn’t burn, and it stays liquid across a wide range of temperatures. Food warehouses that rely on constant cooling—think frozen vegetables, meats, and even vaccines—have switched to it in their refrigeration loops. Regulations about toxic leaks keep getting tighter, and operators see potassium formate as a way to future-proof their businesses. It carries less risk if a leak happens, and food processors don’t have to worry about chemical contamination sneaking into their products.

Potassium formate also finds a place in industrial cleaning. Regular solvents for removing tough grime often come loaded with volatile chemicals that aren’t great for human health or the environment. Potassium formate rinses away more cleanly and doesn’t stick around in the waste stream. For factories trying to cut hazardous chemicals, this shift can help with health and permit requirements.

Potassium formate isn’t perfect. Prices tend to run higher than basic rock salt or traditional fluids, so some companies hesitate. If you think about it, though, there’s a cost to corrosion, pollution fines, and workplace injuries. Upfront, it seems pricey. Over a whole season or project, reduced damage, easier disposal, and fewer regulatory headaches start to add up. Factories and airports take a close look at these long-term payoffs, especially as public pressure for sustainable choices grows.

Science doesn’t stand still. Researchers are testing formate-based coatings, fertilizers, and more sustainable industrial solvents. As resource limits pinch, decision makers look for materials that work hard but don’t trash the planet. In my experience, digging beneath the label reveals the value of chemistry’s unsung heroes like potassium formate. They offer a way to balance performance, safety, and responsibility—needs that affect everyone far beyond the lab bench.

Potassium formate pops up quite a bit in industry. Sometimes workers use it as a de-icer at airports, other times companies count on it for oil drilling or as a laboratory reagent. It’s a salt, plain and simple, but carrying out messy jobs with chemicals always raises the question: Is it safe? From my own days in a cold warehouse, I remember bags labeled with plenty of warning stickers, even for materials that looked pretty tame.

No chemical is a toy, even those considered “low risk.” Potassium formate isn’t one of the aggressive heavy-hitters like concentrated acids or powerful solvents. It doesn’t catch fire by accident, nor will it eat through your skin at the first touch. Toss a pinch on your hand, and odds are nothing much will happen—chemically, it acts a lot like standard table salt. But ask any safety officer or lab manager and the advice sticks: gloves, goggles, and a sense of respect. Respiratory protection makes sense for people who risk breathing in its dust. I’ve seen friends forget this for “mild” substances, only to cough for an hour or nurse an annoying rash for days. Chemical exposure can be sneaky.

Potassium formate isn’t toxic like cyanide, but concentrated contact dries skin, causes irritation in your mouth or eyes, and, in big doses, disrupts the body’s electrolyte balance. The Centers for Disease Control and Prevention highlights that swallowing a lot could trigger nausea or vomiting. Spills don’t lead to emergency hazmat calls, though routine cleanup with basic gloves and eye protection keeps accidents at bay. That’s the thing with even mild salts: Enough contact, or sloppiness day after day, stacks up over the long run. I’ve spotted plenty of workers shrug off powdery spills—until hands start itching or eyes go red.

Government safety agencies don’t consider potassium formate a major threat. The Occupational Safety and Health Administration, for instance, has no special restrictions on it. That’s a good sign, but it doesn’t mean anyone can ground up bags of it and throw it in the break room. Industry veterans know that long-term exposure, even to “harmless” chemicals, can build up risk over time. It’s smart to keep good ventilation in large storage areas. Dust floating around isn’t good for the lungs, no matter how “safe” the label claims.

Common sense and practical habits count for more than fear. Wear gloves. Keep chemicals off your skin and away from your face. Store the stuff in a dry place, away from strong acids, just like you would with many other salts. Prompt cleanup prevents slippery floors and stops the spread of dust. Workers who have experience know that PPE may seem unnecessary for just one bag, but day after day, the little exposures add up. No one wins a medal for ignoring safety, but you can sure lose days to rashes, complaints, and regulatory headaches if things go badly enough.

Safety always improves when teams know the materials on their floor. Regular safety briefings, easy-to-read instructions, and accessible safety data sheets—these things move faster than myth or guesswork. I’ve found companies that make this stuff easy have fewer accidents and happier crews. Potassium formate, handled right, doesn’t frighten most folks. Good habits just give peace of mind, and that’s worth the few seconds it takes to pull on gloves and goggles.

Potassium formate isn’t some mystery compound lurking in your high school chemistry book. Its chemical formula, HCOOK, spells out the essentials—a blend of potassium, carbon, hydrogen, and oxygen. For folks used to sodium chloride or glucose, this formula feels straightforward. One potassium ion, one formate group; nothing hidden, nothing extra. Watching it dissolve in water reminds me of winter’s battle with frozen streets. Potassium formate’s salt structure lets it work as a deicer, helping cities keep cars moving and sidewalks safe.

The value of potassium formate often shows up outdoors or at drill sites. In icy conditions, people want something kinder to concrete, safer for pets, and more eco-friendly than old-school salts. HCOOK delivers on that promise. The formate part, derived from formic acid, breaks down faster in roadside soils than chloride does from rock salt. That means less mess in local streams and less damage to trees or garden beds. In the oil field, the compound’s predictable structure means drilling fluids keep their strength and avoid nasty surprises underground.

Every chemical in our world becomes a talking point when you start looking downstream. I’ve seen folks worry over every product label, and I’ve done the same. With potassium formate, science offers some reassurance. Life on earth deals with many formates every day; our bodies even make formate as a side product of metabolism. HCOOK doesn’t stick around in water like certain heavy metals, and plants or bugs in the soil handle reasonable levels without a fuss. That gives peace of mind, though keeping any runoff in check always makes sense. Still, carelessness can cause headaches—excessive use raises the potassium content of soils, which disrupts delicate plant balances over time.

Most people meet potassium formate as a snow-melting substance or a part of industrial fluids. Price and supply can be hurdles when cities want to switch over or when oil fields run into unexpected demand spikes. Working in landscaping, I’ve seen budgets stretched by material costs, especially if you go for safer but pricier options. The challenge: balance safety, effectiveness, and environmental impact without breaking the bank. Engineers and city planners work closely with manufacturers to find ways to use just enough product—to avoid throwing money and resources down the drain, both literally and figuratively. Portion-control systems and careful monitoring help keep applications where they belong, rather than leaching away to waste.

Potassium formate offers one of chemistry’s simple lessons: Formulas can point to usefulness far beyond the lab. When people invest thought in both what a compound is and what it does outside textbooks, better solutions often emerge—from safer roads in winter to reduced risks for local wildlife. By not losing sight of what’s in the bucket or barrel, we avoid mistakes that follow us for years. The conversation about HCOOK isn’t just about numbers and symbols; it’s about using those tools to build better outcomes, wherever real-world needs come up.

Potassium formate isn’t a word people toss around at dinner, but anybody dealing with industrial fluids or de-icing airports knows its value. This salt often ends up in drilling fluids or runway de-icers thanks to its low crystallization point and environmental footprint. It keeps planes safe during winter and helps oilfield teams get out the resources needed for our daily comforts. That said, handling chemicals with more care than your weekly groceries makes sense—especially since this substance comes with its own risks.

Potassium formate wants stability and a safe spot to call home. Once moisture breaks through, it can clump, dissolve, or ruin any chances for precise dosing. Keeping the substance dry keeps workers from dealing with slippery messes and wasted inventory. Bags or drums sealed tightly save both money and hassle. Not every storage room offers the same protection from ground up, so setting storage up off the floor avoids problems with accidental leaks or water tides during heavy rain.

I’ve seen careless storage ruin jobs. Once, a vendor delivered pallet after pallet of potassium formate right before a storm. The warehouse roof decided it didn’t want to cooperate that night. By morning, several bags sat in puddles. The loss tallied up to thousands of dollars, and a week of project delays. A detail as simple as a high rack and a quality tarp would have saved the day—and the bottom line.

Closed storage without airflow can cause headaches for any shop manager. Potassium formate draws water from the air, so in a humid space, it turns sticky and hard to handle. Air circulation beats back mold or condensation before problems start. If things warm up beyond everyday room temperatures, you might notice shift in weight or lumps forming. Cool, dry rooms help prevent these issues and leave fewer surprises for the morning shift.

Potassium formate sounds less scary than many chemicals, but it isn’t a household friend. Eyes and skin appreciate a barrier. I’ve cracked open a bag carelessly before, only to realize my gloves weren’t up to the job after a few hours of tingling hands. Good gloves, eye protection, and nearby water for rinsing can make tough days less memorable for the wrong reasons. OSHA guidelines back up the real-life need for basic safety here; skipping those leads to regret and report forms no one enjoys filling out.

I once saw two similar white powders on the same shelf—one was potassium formate, the other was far more dangerous. Sharp, clear labels saved a junior tech from adding the wrong one to the tank. Readable, chemical-resistant labels keep not just the paperwork straight, they keep crews safe and operations moving. Rotation also keeps older supplies from expiring and causing issues down the line.

Investing upfront in solid storage pays off. Shelving built to hold heavy drums stands up for years, while proper covers and climate controls help cut headaches. Training everybody—old hands and new hires alike—keeps everyone on the same page. No one wins from cavalier habits with chemicals, even ones that seem low-risk. With the right storage, potassium formate does its job without drama, and the folks managing it head home safe and satisfied at the end of every shift.

Potassium formate has turned up as a strong alternative for keeping runways and roads safe in icy conditions. Most airports try to avoid the classic sodium chloride solutions that can corrode metal and eat away at concrete. Potassium formate does less harm to road surfaces and is less toxic for plants and animals by the roadside. Planes flying in winter weather need quick, reliable takeoffs, and this chemical delivers quick melting action. Some municipalities that face harsh winter storms have made the switch too, aiming to reduce long-term repair bills and environmental complaints.

Industrial sites, big refrigeration plants, and breweries often run liquid chillers to keep things cold and production steady. Potassium formate, dissolved in water, works well as a secondary refrigerant. The fluid moves smooth and carries heat efficiently. Its thermal properties allow companies to run colder without the risk of pipes freezing or bursting. Unlike some glycols and ammonium-based fluids, potassium formate doesn't leave behind sticky residues or cause major corrosion, making maintenance friendlier on the wallet.

Drilling for oil or gas gets complicated when salt beds and other tough conditions threaten to stall crews. Potassium formate has stepped in here, too. It works as a brine in drilling and completion fluids, letting teams drill deeper without facing the high pressures and temperatures that traditional brines can't handle. It helps keep the drilling equipment running well, avoids clay swelling and wellbore collapse, and improves overall extraction rates. Companies also value the fact that potassium formate is more biodegradable and less hazardous than many old-school drill fluids. That environmental track record matters more now, with stricter rules and communities that watch for spills.

Potassium formate may help break some old habits, especially for companies trying to cut their environmental impact. Deicing chemicals like urea and sodium chloride add to runoff problems in streams and lakes. With potassium formate, waterways take a lighter hit. According to research shared by the International Journal of Environmental Research and Public Health, potassium formate tends to break down faster and doesn't promote algae blooms the same way. That benefit keeps aquatic ecosystems healthier and lets cities meet tougher water standards.

While it doesn't fill every shelf in a chemical plant, potassium formate finds work as a reactive agent in certain chemical syntheses. Labs use it for producing special formic acid derivatives and in a few niche metal-treating processes. When I spent time around industrial chemists, they pointed out that, compared to more volatile salts, potassium formate comes with fewer shipping restrictions, cutting headaches for logistics staff. These seemingly small details matter. Even a little less red tape or a clearer safety data sheet can smooth business.

Cost keeps potassium formate out of some markets; people weigh its price against familiar salts. Still, as stricter regulations hit water quality and infrastructure protection gets more costly, more industries give it a second look. Chemical suppliers keep working on cheaper production methods. Years ago, it felt exotic to see potassium formate outside lab shelves. Now, I hear of airports and oil rigs treating it like a workhorse. Companies that want to run cleaner and cut risks gradually put more trust in this adaptable chemical.

| Names | |

| Preferred IUPAC name | Potassium methanoate |

| Other names |

Potassium methanoate Formic acid potassium salt |

| Pronunciation | /poʊˈtæsiəm ˈfɔːr.meɪt/ |

| Identifiers | |

| CAS Number | 590-29-4 |

| Beilstein Reference | 1713886 |

| ChEBI | CHEBI:63005 |

| ChEMBL | CHEMBL1201797 |

| ChemSpider | 11829 |

| DrugBank | DB15644 |

| ECHA InfoCard | ECHA InfoCard: 03-2119940830-42-0000 |

| EC Number | 209-677-9 |

| Gmelin Reference | Gmelin Reference: "15187 |

| KEGG | C18697 |

| MeSH | D016613 |

| PubChem CID | 23665417 |

| RTECS number | UF9100000 |

| UNII | 8KQ3186TZE |

| UN number | UN 3474 |

| Properties | |

| Chemical formula | KHCO₂ |

| Molar mass | KCO2H: 84.115 g/mol |

| Appearance | White crystalline powder or colorless liquid |

| Odor | Odorless |

| Density | 1.56 g/cm³ |

| Solubility in water | Very soluble |

| log P | -3.6 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 3.75 |

| Basicity (pKb) | pKb: 10.25 |

| Magnetic susceptibility (χ) | +18.0e-6 cm³/mol |

| Refractive index (nD) | 1.370 |

| Viscosity | 1.9 cP (20°C, 71% solution) |

| Dipole moment | 1.51 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 96.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -617.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -617.0 kJ/mol |

| Pharmacology | |

| ATC code | B05XA17 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Keep only in original packaging. Wash hands thoroughly after handling. Wear protective gloves/protective clothing/eye protection/face protection. |

| Autoignition temperature | Autoignition temperature: 600°C (1112°F) |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 oral rat 5500 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Potassium Formate: Oral, rat: 5500 mg/kg |

| NIOSH | RTV |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | REL 2 mg/m³ |

| Related compounds | |

| Related compounds |

Formic acid Potassium acetate Sodium formate Potassium carbonate |