Aluminum sulfate traces its practical uses deep into the 18th century, known then as “alum.” Textile workers and paper manufacturers first adopted it to fix dyes and size paper, long before modern chemistry defined its structure and utility. Entering the industrial revolution, people noticed aluminum sulfate could clarify water, leading cities to experiment with its potential in water treatment. Its simplicity and wide availability kept it popular as cleaner water became a public health issue. Looking through the history books, anyone can see how a need for safer drinking water, brighter fabrics, and more robust paper placed aluminum sulfate in the toolbox across multiple trades. Old records from mills and water boards show orders for this compound grew year after year. Learning from that century-old journey highlights why this chemical keeps showing up in public works projects or even school science labs.

Aluminum sulfate emerges as a white crystalline solid, usually sold in granular, powder, or sometimes block form, with a noteworthy astringent taste. Large chemical suppliers and small hardware stores both line their shelves with the substance under names like “alum” or “papermaker’s alum.” The packaging often tells the same story: a reliable coagulant and cleaning agent for water, a builder for pigments and dyes, or an additive in gardening to help hydrangeas turn blue. Its production scale remains immense, driven by constant demand in municipal treatment plants and industries alike. With production in the millions of tons, its importance rivals many better-known chemicals people encounter more often in daily life.

This compound presents as a white, odorless solid. Its solubility in water stands out. Drop it into a glass of water, and the crystals dissolve fast, releasing heat and breaking into positively charged aluminum ions and negatively charged sulfate ions. Aluminum sulfate won’t melt until heated past 770°C. Grinding the solid into a fine powder makes it dissolve even more quickly. Even a small amount can drop the pH of water, making it more acidic. The taste—sour, puckering, and unforgettable—reminds those who work with it to keep it away from food. Under careful handling, aluminum sulfate doesn’t create fumes, and isn’t volatile or explosive, so storage rarely becomes a major safety hazard.

Suppliers aim for a clear label, making sure anyone holding a bag or drum knows what’s inside. Pure aluminum sulfate sold for laboratory or pharmaceutical use may boast a purity greater than 99%, while industrial batches can drop a bit lower, sacrificing some purity for price and throughput. Typical labels list the presence of any impurities, water content (since commercial grades generally include bound water), and sometimes chloride or iron levels, both important for sensitive uses in pharmaceuticals and specialty papers. The UN number, CAS number, shelf life, and hazard codes stand out for anyone needing a quick reference in an emergency. Many manufacturers also note compliance with standards from agencies like the American Water Works Association or the U.S. EPA, useful for environmental engineers who need dependable, trackable chemicals.

Most commercial aluminum sulfate originates from the reaction of aluminum hydroxide or aluminum trioxide with sulfuric acid. This method creates a highly soluble form, blending the metallic and acid components efficiently. In many industrial settings, reactors piped with corrosion-resistant linings handle the hot, exothermic process that results. The chemical equation reads straightforward: aluminum oxide plus sulfuric acid forms the hydrated sulfate plus water. For specialties used in pharmaceuticals or food, manufacturers start with a purer base, control heating and reaction times precisely, filter the mixture, and crystallize the product at controlled rates. These steps weed out unwanted byproducts and deliver a product trustworthy for sensitive tasks.

Drop aluminum sulfate in water, and an interesting chain of reactions begins. It doesn’t just dissociate; it hydrolyzes, making aluminum hydroxide and sulfuric acid. This hydrolysis grabs contaminants or suspended solids in water, binds them up, and lets them settle – the heart of its success as a flocculant. Some industries modify aluminum sulfate after production, making “double salts” by combining it with potassium or ammonium salts, or reacting it with sodium carbonate to make alumina. Adjusting its composition this way fine-tunes its properties for the task at hand. In making pigments and lake dyes, aluminum sulfate reacts with various organic anions, turning into colorful and chemically stable complexes.

Many know it as alum, especially in traditional contexts like pickling or textile printing. Chemists write it as aluminum sulfate, but you can read “papermaker’s alum,” “cake alum,” or “pearl alum” on labels, depending on the product’s target market. Some industries lean on the name “alumina sulfate,” emphasizing the aluminum source, while water treatment workers often shorthand it as “alum powder.” On a global level, you’ll see “aluminio sulfato,” “sulfato de aluminio,” and similar translations in trade catalogs. Folks working across countries keep an eye on names, since the standard can shift without warning in procurement or customs paperwork.

Those handling aluminum sulfate take precautions to avoid skin or eye contact. It irritates unprotected skin and can damage eyes—goggles and gloves aren’t optional in busy plants. Workplaces follow stringent rules for storage, keeping the chemical in sealed containers, away from strong bases or reactive metals that could spark hazardous reactions. Spills get swept or vacuumed up, seldom flushed with water because that can trigger a slippery mess. The EPA classifies aluminum sulfate as relatively low risk—but only when handled with respect. Untrained workers can end up with chemical burns or inhalation risks if they ignore standard procedures. In water treatment, process monitoring ensures the right concentration. It’s easy to overdose a tank and drive the pH too low, causing new headaches downstream.

Water and wastewater treatment claim the lion’s share of aluminum sulfate demand. Municipal plants rely on it daily to bind up silt, bacteria, and other tiny debris, leaving millions with clear drinking water. The papermaking world uses it to size paper and improve ink adhesion, producing smoother, crisper pages in everything from books to cardboard boxes. Textile dyeing wouldn’t have advanced nearly as far without aluminum sulfate’s mordant properties, which anchor colors deeply into fibers. Gardening stores sell it for soil acidification, prized by growers keen on colorful hydrangeas. In the food world, it works as a pickling agent or dough softener, though regulations cap how much goes into the bread or pickles on supermarket shelves.

Aluminum sulfate continues to draw the attention of chemists and engineers chasing more sustainable purification options. Recent trials in water treatment look at blending it with new flocculants or tailoring its particle size to boost contaminant removal. Papers from research institutes consider its use in advanced ceramic creation and as a catalyst in synthesizing specialty chemicals. Some teams investigate how its reactivity might change when mixed with biopolymers, seeking “greener” paper manufacturing processes with lower chemical residues. Collaborations between universities and industry keep churning out patents for process tweaks that squeeze out higher purities, cut energy usage, or prevent hazardous byproducts—key to keeping the industry both profitable and cleaner.

Much of the discussion about aluminum sulfate turns to potential health impacts. The chemical itself stays relatively harmless in diluted form, but high doses have caused acute toxicity in mishandled treatment plants. Chronic exposure to aluminum compounds links in some studies to neurological issues, though the direct risk from water treated with proper alum doses remains low by regulatory standards. Research from toxicologists and epidemiologists keeps governments on their toes. The Flint water crisis and similar stories sparked fresh concerns about how aluminum could interact with pipes or other additives, leading agencies to tighten oversight. Animal studies draw lines between safe and harmful concentrations, and the World Health Organization updates guidelines as more data arrives. Keeping public trust healthy means transparency: constantly updating the science on environmental and physiological effects, and publicizing those results along with routine water safety assessments.

Demand for aluminum sulfate doesn’t show signs of fading. As cities tackle aging infrastructure and new contaminants, water engineers eye refinements to existing treatment protocols using aluminum sulfate, blending it with novel materials to stretch its range. The shift toward sustainable manufacturing has suppliers ramping up recycling programs to capture and reuse aluminum from industrial waste. Advanced materials researchers also test derivatives of aluminum sulfate for battery technology, ceramics, and even targeted drug delivery—areas well beyond its early uses. Both regulation and innovation nudge the industry to develop safer, lower-waste production methods and tighter product specifications. For the curious, this all spells an active, evolving field where science, policy, and technology meet practical daily needs.

One of the most familiar uses of aluminum sulfate shows up in the water pouring from kitchen faucets. Plants add it to the water supply during treatment. The product reacts with impurities, causing them to clump and sink, so those particles can be filtered out. People might overlook the process, but this step brings clearer drinking water into homes. In some small towns where the tap still carries a strange taste or color, the lack of enough chemicals like aluminum sulfate often plays a part. The Centers for Disease Control and Prevention reports that safe drinking water greatly lowers disease risk and keeps communities healthier.

Aluminum sulfate also acts as a helper for making paper. Many people don’t picture a bright white sheet of office paper as a chemical product, but that smooth finish and even color come partly from this compound. In the papermaking process, it changes the tiny wood fibers so they stick together better. It also adjusts the acidity of the mix, letting dye and colorants hold fast. Long before digital devices, paper traced the flow of knowledge and business, so refining quality never stopped mattering. Every invoice, report, and school handout benefits from chemicals like this, working behind the scenes.

Gardeners sometimes look for aluminum sulfate to change soil conditions. Many garden plants, like blueberries and hydrangeas, do best in acidic ground. Sprinkle some on, and the soil’s pH falls, making it more welcoming for acid-loving roots. Yards left fallow or doused with lime often swing the pH too high. Aluminum sulfate brings it down without much fuss. Experienced gardeners watch plant color and shape to decide what the soil really needs. Bluer hydrangeas serve as a natural signal that the pH dropped as planned.

In fabric mills, workers face the problem of getting dyes to stick and stay true, wash after wash. Aluminum sulfate, sometimes called alum, lands a place in this work too. The chemical helps fabric fibers grip the color tightly, leading to vibrant clothing and household linens that don’t fade too fast. Factories and craft dyers have used it for generations. Strong color and wash resistance both keep the cost of clothing lower for families, who notice fast and dull dyes only after one or two washes.

Like many industrial chemicals, aluminum sulfate brings up safety and environmental questions. If water treatment plants use too much, it can lower the pH too far, harming fish and plants downstream. Manufacturing the product creates waste that needs strict handling, too. Workers need protection against dust and accidental contact. Safer chemical handling, increased automation, and better safety gear could prevent exposure and limit spills. Agencies such as the Environmental Protection Agency issue guidelines based on these facts.

Communities can support research for water treatment alternatives that use less chemical input or create less waste. Homeowners and gardeners can stick to soil tests, using aluminum sulfate sparingly where really needed. Industry keeps exploring plant extracts and eco-friendlier processes for both textiles and paper. These steps, built on careful use and solid science, protect both public health and the land itself.

People expect the water that flows from their taps to be clear, safe, and tasteless. Many city water plants use aluminum sulfate, or “alum,” as a key part of the filtration process. The stuff has been around for a long time—my hometown utility has relied on it since the 1960s. It’s a coagulant that gathers dirt, bacteria, and other tiny particles so they can be pulled out before reaching your glass. This method, recommended by health regulators, clears out the gunk you don’t want to drink.

Most water professionals trust the science behind aluminum sulfate because it has decades of successful use. The U.S. Environmental Protection Agency (EPA) and the World Health Organization both set guidelines on the max amount of aluminum allowed in tap water. Tests tend to show aluminum levels way below those limits. For someone who’s worked alongside city engineers and toured treatment plants, the process is about as careful and measured as you could hope for.

Still, people have questions about ingestion. Stories sometimes pop up on social media about aluminum building up in the brain or causing health issues. There's some research digging into connections between aluminum and Alzheimer’s disease, but scientists haven’t found proof that aluminum sulfate in water causes those problems—at least not at the amounts found after normal treatment. Controlled studies would have alerted regulators if there was a serious risk.

For nearly everyone, drinking treated water carries no measurable risk from the aluminum that’s left over. But there’s a catch: those with severe kidney problems cannot clear extra aluminum from their bodies as easily. I remember a neighbor with chronic kidney failure. His doctors advised him not to drink high-aluminum water. Such folks might worry, though again, utilities keep a close eye on their numbers, and bottled or filtered water offers alternatives if needed.

Workers run regular tests, hour after hour, watching the levels. Dosing is precise. If something goes off, alarms go up, and plants can flush out batches that don’t meet standards. This isn't stuff that's left to luck. State and federal agencies check up by reviewing water data, performing their own sampling, and inspecting treatment plants. Water suppliers in towns I’ve lived in post annual water quality reports, listing exact readings of aluminum and lots else.

People who want fewer chemicals look for alternatives. A few plants use iron-based coagulants or natural polymers. These work, but costs and logistics change with each one. Alum offers a known quantity—cities budget for it, and maintenance crews know how it behaves. Switching out means retraining staff, updating old equipment, and banking on results that rarely match alum’s track record. Extensive research backs up what’s in place now.

Safe water matters to everyone. Aluminum sulfate helps water plants deliver clean, reliable drinking water day after day. The solution isn’t perfect, but evidence supports its safety for the vast majority of folks. People should take personal health needs seriously and check treatment reports if they’re uneasy. Utilities and regulators should continue sharing what they find and supporting improvements driven by emerging science. That’s what keeps trust in the water system strong.

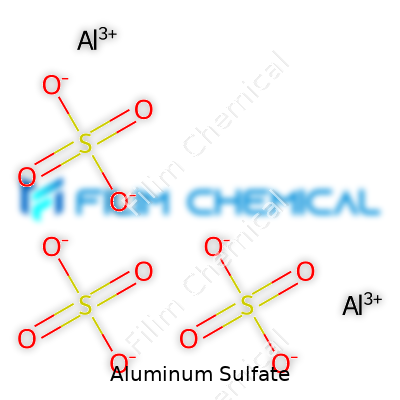

Aluminum sulfate, with the chemical formula Al2(SO4)3, tends to pop up in everyday life more than most people realize. Step into any municipal water treatment plant, and this white crystalline solid is there, quietly working to clean up our drinking water. The formula itself might look intimidating, but really, it points to a compound made from aluminum, sulfur, and oxygen. Every atom in that formula tells a story about the compound’s reactivity and use.

I’ve walked through water treatment facilities and seen aluminum sulfate in massive bags, ready to be mixed with water. The reaction forms a thick, gelatinous substance—floc—that traps dirt and contaminants. Clean water flows out the other side. Many people in developed cities never pause to think about the work behind safe tap water. Aluminum sulfate’s role should not be brushed aside. The World Health Organization estimates that close to one in three people worldwide lack access to safe drinking water. In many countries, this compound keeps communities safe from waterborne illnesses that would otherwise devastate families and economies.

Look at any sheet of white paper. There’s a good chance aluminum sulfate helped make that paper smooth and bright. Instead of using harsh or environmentally hazardous chemicals to prepare the pulp, the industry relies on aluminum sulfate. The process helps bind fibers and improves the paper's texture without releasing unnecessary toxins into the environment. Over the years, I’ve seen papermaking companies switch to more sustainable practices by reducing waste and managing chemical runoff, thanks in part to more control over compounds like aluminum sulfate.

Gardeners know that soil pH makes or breaks plant growth. My own vegetable patch suffered for years because the soil was too alkaline. Adding aluminum sulfate solved the problem, giving me plump tomatoes and healthy basil. Farmers use it for the same reason, adjusting soils for crops that need more acidic conditions. Getting this right means better yields, less fertilizer waste, and steadier food supplies. That matters with food security becoming a growing issue for millions worldwide.

No chemical comes without risks. Prolonged exposure to aluminum sulfate dust irritates the respiratory tract. Spills in waterways can disrupt aquatic ecosystems. I’ve read reports where improper storage or transport causes costly and dangerous accidents. Companies and municipalities need to train staff, monitor air quality, and invest in safer handling systems. Setting up clear response protocols helps protect both people and the environment.

Innovation in chemistry keeps moving. Scientists develop alternative coagulants for water, some based on natural materials with lower environmental impact. The industry also explores better recycling methods for paper manufacturing by minimizing aluminum sulfate discharge. On the ground, farmers receive practical guidance through workshops and digital tools to apply soil amendments efficiently. Policies that encourage responsible sourcing, transparent labeling, and worker training will drive industry standards higher. Decisions based on real data, rather than habit or hearsay, protect health and the environment.

Aluminum sulfate carries a reputation as both a helpful tool and a hidden hazard. You’ll spot it in water treatment plants, paper mills, even in some gardening products. From my own foray into industrial safety audits, the way people store and handle this substance matters much more than official manuals suggest. I’ve seen everything from barrels sweating in humid corners to sacks slumping open on dusty warehouse floors. Tiny lapses amplify risk.

Sometimes the obvious escapes attention. Moisture deserves instant respect. Exposed aluminum sulfate draws in water, forming a sticky mess that clogs machines and corrodes containers. Once, I visited a municipal works yard after a spell of wet weather. Rust and goo sat pooled beneath old bags, and the crew had to junk a full pallet. The cost stings, not just from waste, but from the cleanup and risk of release.

Storing this chemical in a dry, well-ventilated spot isn’t fancy advice—it’s common sense that pays for itself. Above-ground racks and plastic covers work better than concrete floors. Even a plastic drum needs a tight lid. Sealed containers and quick cleanups after spills keep the mess in check.

One mistake I keep seeing, especially in smaller facilities, comes down to stuffing incompatible chemicals together for convenience. Aluminum sulfate reacts if stacked near alkalis or chlorinated materials. Mixing powders might kick off a chemical reaction, making a bad situation worse. Segregated storage isn’t bureaucracy—it keeps real problems off your plate.

Labels matter. Faded or handwritten scrawls cause confusion, especially during shift changes. Spend a little more on proper signage, and spend less time sorting out mysteries.

Skin irritation comes up often, evolving from a minor rash after a single splash to chronic problems with frequent handling. I still remember the sting from a drop that snuck under my glove. Beyond gloves and goggles, having handwashing stations within reach makes it far easier for workers to keep exposure low. Common sense practices prevent most issues: long sleeves, closed shoes, and actual enforcement of safety gear rules.

Breathing in the dust turns into a headache, literally and figuratively. Workers complain of dry throats and coughing fits, more than any safety sheet warns. Dust control through proper storage, keeping bags covered, and, where possible, gently pouring instead of dumping minimizes this hazard. A simple mask—P2 or better—can cut down on complaints dramatically.

Nobody truly learns safe chemical handling from a single PowerPoint. Experience, reinforced by walk-throughs and practical drills, sticks far better. I’ve met warehouse staff given twenty minutes of computer-based training, then expected to juggle dozens of unfamiliar chemicals. A regular, hands-on approach—where folks actually walk through the process—pays off in fewer incidents.

Reporting small spills or cracked containers protects everyone downstream. Front-line workers know the risks best, but only if the culture rewards honesty over quick fixes. Plant managers who put safety conversations on the daily routine set the tone.

Getting aluminum sulfate storage right isn’t rocket science, but it does demand steady attention and respect for the material’s quirks. The price for ignoring the basics? Costly waste, sidelined workers, and at worst, regulatory penalties. What works: keep it dry, keep it separate, keep it labeled, and make sure people know how to protect themselves. These habits stick much longer than any poster on the break room wall.

A lot of folks know aluminum sulfate by another name—alum. City water utilities and backyard gardeners both reach for it. In water treatment plants, it’s used to clump stuff together, making it easier to filter bad things out. High school chemistry teachers sometimes use it to show how chemicals react. You can even spot it in pickling recipes and in some deodorants.

The biggest health questions usually pop up in cities, where workers use aluminum sulfate to help clean up drinking water. There’s an ongoing debate about how much aluminum makes its way from water plants into taps. According to the World Health Organization, average treated water gives people a lot less aluminum than you’d get from food, especially things like baking powder or processed cheese. Normally, people flush aluminum out of their systems with no trouble.

Trouble can start if someone has kidney disease. Their bodies don’t handle metals as fast, so aluminum can accumulate. Studies have linked too much aluminum in the body to nerve issues, bone pain, and some rare diseases, especially when kidneys stop doing their job. Doctors and public health workers agree that regular folks with healthy kidneys face little danger from the levels found in treated water.

Pumping chemicals into water to make it safer for people raises questions about what happens to creeks, ponds, and the dirt outside water plants. Farmers sometimes use aluminum sulfate to knock down phosphorus in runoff water, which can be a big help in stopping algal blooms—those smelly, green messes in lakes. Too much phosphorus means too much algae, which zaps oxygen and suffocates fish.

Even though aluminum sulfate helps control phosphorus, it has its own risks. Research shows that aluminum can build up in wet, acidic soils and ponds. If the pH drops—soil scientists call it “going sour”—aluminum turns more water-soluble. Fish and other aquatic species can absorb it, which can stress their gills and make it hard for them to breathe. Edible plants have roots that can absorb aluminum, especially in bad soils, but heavy contamination isn’t common without industrial waste.

Public agencies have set strict limits on how much aluminum should be allowed in tap water and discharged into rivers. Water treatment operators carefully test pH and other factors to stop aluminum from running wild. For gardeners, careful measuring and not overusing alum helps cut down risks. In schools, science teachers remind students to treat chemicals with respect, wash hands, and never taste-test in class.

The Environmental Protection Agency, World Health Organization, and dozens of local regulators keep updating their advice as new research comes out. People who use private wells sometimes have it worse, since nobody else is tracking what’s in their water. Regular testing and connecting with local experts lets folks catch problems before they get serious.

Safer handling at every point—farms, treatment plants, classrooms—helps protect both people and the environment. Backing up rules with checkups, better reporting, and spending time on community education keeps everyone ahead of the curve.

| Names | |

| Preferred IUPAC name | aluminum sulfate |

| Other names |

Alum Cake alum Dialuminum trisulfate |

| Pronunciation | /əˈluːmɪnəm ˈsʌlfeɪt/ |

| Identifiers | |

| CAS Number | 10043-01-3 |

| 3D model (JSmol) | Aluminum sulfate JSmol 3D model string: ``` Al2S3O12 ``` |

| Beilstein Reference | 3589903 |

| ChEBI | CHEBI:29974 |

| ChEMBL | CHEMBL1201558 |

| ChemSpider | 15744 |

| DrugBank | DB11239 |

| ECHA InfoCard | ECHA InfoCard: 027-003-00-2 |

| EC Number | 10043-01-3 |

| Gmelin Reference | 1620 |

| KEGG | C14326 |

| MeSH | D010058 |

| PubChem CID | 24850 |

| RTECS number | WS5690000 |

| UNII | 9Z8V8VZ4IJ |

| UN number | UN3264 |

| Properties | |

| Chemical formula | Al2(SO4)3 |

| Molar mass | 342.15 g/mol |

| Appearance | white crystalline solid |

| Odor | Odorless |

| Density | 2.71 g/cm³ |

| Solubility in water | 36.4 g/100 mL (20 °C) |

| log P | -2.3 |

| Acidity (pKa) | ~3.3 |

| Basicity (pKb) | 2.7 |

| Magnetic susceptibility (χ) | −5.5×10⁻⁶ |

| Refractive index (nD) | 1.470 |

| Viscosity | Viscous |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 343 J/(mol·K) |

| Std enthalpy of formation (ΔfH⦵298) | -1560 kJ/mol |

| Pharmacology | |

| ATC code | A12AB01 |

| Hazards | |

| Main hazards | Causes severe skin burns and eye damage. Harmful if swallowed. |

| GHS labelling | GHS07, GHS05 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. H335: May cause respiratory irritation. |

| Precautionary statements | P264, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-0-1-Acidos (acid) |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 oral rat 1930 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral (rat) 6207 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | 2 mg/m3 |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Aluminum chloride Aluminum nitrate Aluminum hydroxide Aluminum oxide Ammonium aluminum sulfate |